- Taurus 3 Ring Saw

- Taurus Blades

- Magnificent 7

- Accessories

- Manual & Parts

- Taurus 3 Tips

- Videos

Taurus 3 Ring Saw

A Shape Cutting saw

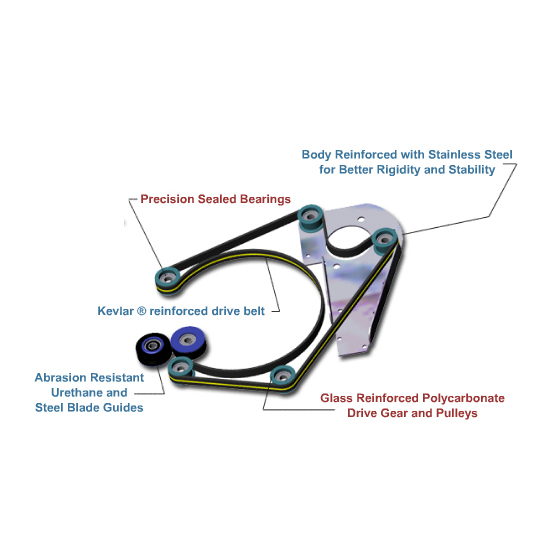

The Taurus 3 Ring Saw is an advanced shape cutting saw. We believe that you will find the all new patented Taurus 3 "Ring Saw" the most important key to unlocking your imagination and speeding you on your way to creating new and wonderful shapes never before possible.

The Taurus 3 incorporates many new capabilities most of which have come from listening to you, our  customers.We believe you will find these machines easy and fun to work with.

customers.We believe you will find these machines easy and fun to work with.

The ring saw is a completely unique machine and its operation is very different than any other machine. For this reason persons who have been using band saws tend to lead the material into the front of the saw blade and rotate the material to make a curved cut.

**All cuts on the Taurus Ring Saw can be made by moving the material forward, backward, left and right so rotation is not necessary. Diagonal directions are the strongest.

- 17 3/4" x 16" work surface.

5 5/8" throat depth.

1 1/2" throat height.

1/5 horse power motor.

110 volt or 220 volt (w/ internal transformer) capacity. 1.3-1.7 amps

- 1 Standard Ring Blade (installed).

Integrated spot light.

Removable face shield.

1 Stabilizer Foot

1 Instructional DVD as well as a written instruction manual.

- Bottom door ( soak bottom door in water before using to lubricate blade).

Thumb screw.

Bottom door clip.

The Taurus will cut all kinds of materials

These materials will not load the blade. They include but are not limited to:

- tile

- gold (which can be refined out of the water bath)

- silver

- brass

- bronze

- aluminum

- stainless steel

- copper plastics such as lucite

- plexiglass

- composites and all types of stone

The Taurus can be used as a high speed coping saw and will greatly reduce your metal cutting time. Slight loading can occur with aluminum over a period of time. Periodic cutting on a piece of brick will remove it from the blade.

The Taurus 3 Becomes a Hand Saw

This versatile saw can be used as a Hand Saw simply by removing the saw portion from the unit. You know longer have to bring the material to the saw, instead, take the saw to the material you want to cut.

Use the Stabilizer Foot any time you want better control. But.....Always use the Stabilizer Foot when using the Taurus 3 Ring Saw as a Handheld Saw.

The Stabilizer Foot is now included with your purchase and it provides greater blade stabilization which in turn reduces grommet wear and gives you far better control.

To learn how to use the Taurus 3 Ring Saw as a Handheld Saw, please refer to the Instruction Manual and Video Support by clicking on the appropriate tabs on this page.

Taurus 3 Blades

Taurus 3 Blade Kits

All Taurus 3 blade kits come with one blade and

two orange groove grommets.

Taurus II.2 Blade Kits

All Taurus II blade kits come with one blade, three yellow groove grommets,

four red gear grommets and two hole reducers.

Dichroic Blade

Just for cutting thin Dichroic Glass. This blade has the popular slim blade design with a fine diamond grit that will not chip the delicate dichroic finish! Also works well with iridescent coated glass allowing you to form intricate shapes with perfect edges. Clean edges mean lower temperatures and faster firing times for kiln fired jewelry creating a clean professional look.

Standard Blade

For general use, Omni-directional. The Standard blade gives you strength as well as versatility in all materials. Because the blade is round you have the ability to cut in any direction. The 360 degree diamond coating allows the blade to cut quickly while grinding the edge, leaving it smooth.

Separating Blade

For internal cuts, omni-directional. The Separating blade is the same size as the Standard blade and has exactly the same cutting action. The difference is that the Separating Blade is made from a stainless steel wire that is coated with the same high quality process as all our blades and then has a coupling attached to it which is also coated for protection and smooth action. This blade gives you the ability to open the blade, slide it through, reattach and make internal cuts with no entry point.

Slim Blade

For the most intricate designs, omni- directional. The Slim blade offers the most intricate cutting ability of all our "Ring Blades". Because of the Slim blade's diminutive size, it has greater ability to create intricate designs and is ideal when cutting non-ferrous metals but at the same time takes away strength so it is recommended only when its size is beneficial.

Note: Smallest kerf size available for Taurus II.2

Mega Blade

For dense materials. Because of its "tear drop" shape, the Mega Blade is our strongest blade ever. To date, no one has been able to break one. This blade is used differently than our Omni- directional blades. It is cuts mainly on the front and back, so to create a curve you will guide the material around the blade.

The Mega blade is so rigid that it has the ability to damage the saw itself if used improperly by pushing too hard. So keep in mind the "golden rule" to let the saw do the cutting and do not force the material.

Slicer Blade

Thinnest curf ever for Taurus 3. The Slicer blade is ideal when removing the least amount of material is desired. This blade gives you the ability to use more of your material and as a byproduct actually cuts faster than any of our "Ring Blades".

It is highly recommended for use with our Super Slicer. The Slicer blade is flat, giving it strength when cutting forward and backward, because of this, the cutting will only be from the front and back. Cutting from the sides will not only be very slow but will damage the grommets.

Be sure to Always look for the Gemini Seal to ensure you are buying Genuine Gemini Saw Parts!

Blade Compatibility

Taurus II Blades

- Standard Blade

- Separating Blade

- Slim Blade

- Dichoic Blade

Taurus 3 Blades

- Standard Blade

- Separating Blade

- Slim Blade

- Mega Blade

- Slicer Blade

- Dichroic Blade

- Speed Blade

The Magnificent 7 Blades of the Taurus 3

There are 7 blades available for the Taurus 3 ring saws and there are often questions arising as to what they are for, how long they last, and how to use them. So we are writing this article to provide a summary of all of them and their many uses. There are now seven blades to choose from.

There are universal truths about all of the blades that hold true for all of them:

1) All blades cut the same materials: glass, tile, stone, shell, nonferrous metals, hard plastics such as acrylic and lexan, and anything that has a similar density to these materials.

2) All blades use the same belt and grommets. Blades are interchangeable with the same belt and grommets and do not need to be changed unless they are excessively worn.

3) Always let the blade do the cutting. Forcing the blade through the material in a hurry will not only cause a slower cut but can also shorten the blade life. There is an optimum speed for each blade in each material; you can feel it while you are cutting. Sensitivity to this causes extremely long blade life Defined it is that point at which you get maximum cutting speed for minimal pressure.

The Magnificent Seven Serious Blades

Note: When describing blade abilities it is wise not to confuse the ability of a blade to cut a certain material greater thickness once in awhile as opposed to that same blade being used to cut only that thickness all the time. For this description we will refer to blade capacity vs. normal use. When we speak of blade shape it is what is called a cross section which is like snipping off a piece of the blade and looking directly at its end.

Standard Blade - (part# 1042) Stained glass pattern and all around multi purpose cutting blade. Its action is omni-directional. This is to say that it cuts the same speed and kerf, (swath left by the blade), in any direction. This blade was the first blade to be put on saws and makes pattern cutting very easy because the user does not have to turn the piece while cutting but simply move it in any direction.

- Blade Shape: Round .072 Diameter (note 1/16" equals .063 and 1mm equals .0394)

- Grit is aggressive.

- Material Thickness Capacity: 3/8", normal use is 1/8" art glass, 1/4" soft wall tile.

- What to Avoid: Do not use for ceramic tile, 3/8" fused glass pieces, or thick material in general.

- Average Blade Life: 40-60 hours

Separating Blade - (part# 1043) This blade is the same as above but t comes apart or cutting out the center of something without using an entrance cut. You must first drill a hole. Consult your DVD for hole drilling instructions.

- Blade Shape: Round .072 Diameter (note 1/16" equals .063 and 1mm equals .0394)

- Grit is aggressive.

- Material Thickness Capacity: 3/8", normal use is 1/8" art glass, 1/4" soft wall tile.

- What to Avoid: Do not use for ceramic tile, 3/8" fused glass pieces, or thick material in general.

- Average Blade Life: 40-60 hours

Mega Blade - (part# 1045) This heavy duty blade is hungry for whatever you can feed it. It is almost unbreakable so it is great for class settings. It has an opinion about which way it likes to cut because of its shape which is basically tear dropped. The round part of the tear drop faces outward and the pointed part faces inward. This means it cuts faster when pulling towards yourself and slower pushing away and slowest sideways. Its kerf is the same as a standard blade when pushing and pulling but it leaves a wide swath the same as a standard blade when pushing and pulling but it leaves a wide swath sideways. That said you can cut whatever you can fit into the mouth of the saw and the shape allows for creative shaping. Cutting action is omni-directional in thin material like stained glass but more forward and backward cutting for thicker harder materials. Leaves a smooth edge.

- Blade Shape: Tear Drop .072 Diameter (front) x .150 (front to back), inside is pointed.

- Grit is aggressive.

- Material Thickness Capacity: 3/4", normal use is fused glass, stained glass, ceramic tile, or stone.

- You may have to remove the stabilizer foot to use the full 3/4" capacity.

- What to Avoid: Do not cut thin dichroic glass as it will chip easily, demonstrate to students its action prior to letting them use it, explaining the tear drop shape and its unique action.

- Average Blade Life: 50-100 hours

Slicer Blade - (part# 1046) This is our thinnest blade and only cuts forward and backward. It can grind slightly left and right, but take your time and it will turn on a dime or smaller. Its action is just like that of a band saw but infinitely better in that you rotate the material into the blade as you are cutting but you can in the middle of the cut without binding and head off in any direction either backwards or forwards.

This blade was developed for slicing material quickly with a thin kerf (.040, 1mm) and it is the blade we recommend for use with the Super Slicer, (a jig for slicing pattern bars and rods into thin repeatable wafers). Also it has finer diamond so the cut is even smoother than all the other blades except for the dichro blade. Use this blade with the heavy duty flocked belt to avoid splitting. This blade can turn on a dime and do very intricate designs once you get used to it. Glass fusers love it.

- Blade Shape: Flat .040 width x .150 length.

- Grit is fine.

- Material Thickness Capacity: 3/4", normal use is for slicing thin wafers in rods and pattern bars,

and scroll cutting of fused glass up to 3/8" thickness. - Average Blade Life: 50-100 hours

Slim Blade - (part# 1043) Originally developed for the Taurus I thru II.2 series as a thinner version of the standard blade. It has the same dimension as a standard or separating blade front to back but is thinner as you look at it straight on. For this reason it i just as strong as a Standard Blade but can cut quicker front to back and leave a slightly smaller kerf, (.062). It cuts the same as a standard blade left o right and its action is omni-directional.

- Blade Shape: Oval .062 x .072 (front to back).

- Grit is aggressive

- Material Thickness Capacity: 3/8", normal use is 1/8" art glass, 1/4" wall tile.

- What to Avoid: Do not use for ceramic tile, 3/8" fused glass pieces, or thick material in general.

- Average Blade Life: 40-60 hours

Dichroic Blade - (part# 1049) NEW! This is the slim blade but coated it in super fine grit so that it does not chip even the thinnest of dichroic glass. Its cut is super quick and leaves the smoothest edge of all of the blades allows the use of lower firing temperatures in the manufacture of jewelry and the like. Neat crisp edges add a note of professionalism with this blade. Its action is omni-directional.

- Blade Shape: Oval .058 x .072 (front to back).

- Grit is finest.

- Material Thickness Capacity: 1/4", normal use is thinner than normal dichroic or iridized glass.

- What to Avoid: Do not use for ceramic tile, 1/4" fused glass pieces, or thick material in general.

- Average Blade Life: 40-60 hours

Speed Blade - (part# ....) Sometimes known as the inverted Mega blade we turned a mega inside out and made it thinner. The result is a tear dropped shaped blade that is almost unbreakable with the round part on the inside and the point on the outside. Its thinner profile makes it our fastest most aggressive blade yet. When pushing forward into this blade it glides through the thickest toughest materials with ease. It comes with a "Flocked belt" only as this is the only belt that can handle its aggressive nature. Its action is omni-directional in stained glass or soft wall tile and forward and backward for thicker or harder materials. When pushing or pulling the material through with this blade it has a thinner kerf than a Standard, Mega, or Slim blade. (.055).

- Blade Shape: Tear Drop .055 inside x .150 (front to back).

- Grit is aggressive.

- Material Thickness Capacity: 3/4", normal use is fused glass, stained glass, ceramic tile and stone.

Note: you will have to remove the stabilizer foot to use the full 3/4" capacity.

- What to Avoid: Do not cut thin dichroic glass as it will chip easily. Demonstrate to students its action prior to letting them use it, explaining the tear drop shape and its uniqueness. Average Blade Life: 50-100 hours

Taurus I, II, II.2

These saws can use 4 of the previously mentioned blades. They have different part numbers because the grommets are different. Please note the chart below for reference numbers. The description and action of these blades is the same for all saws.

Standard Blade (Part# 1039)

Separating Blade (Part# 1041)

Slim Blade (Part# 1040)

Dichro Blade (Part# 1038)

Taurus 3 Extras

Slicer Blade & Belt Kit (Part# 1051)

Speed Blade and Belt Kit (Part# 1052)

Flocked Belt (Part# 0108) (Made especially for slicer blade and speed blade), this belt is probably overkill for all other blades and it costs a little more. It has a Kevlar flocking or criss crossed webbing that holds the rubber together so that it can't easily split.

Taurus 3 Accessory Kit

This kit is equipped with helpful tools for completing any project, from cutting straight lines to perfect circles and precise angles. This kit can be purchased at your local stained glass supplier or from a Gemini Saw Distributor.

DVD Not Included

DVD Not Included

The Taurus 3 Accessory Kit includes the following:

- Straight Edge

- 30/60 Degree Cutoff Triangle

- 45 Degree Cutoff Triangle

- Bevel Edge Maker

- Circle Maker

- Lamp Wedge

The Straight Edge

The Straight Edge

This tool gives the ability to cut straight lines, which would ordinarily be very difficult, with your

ring saw. Fits anywhere on the saw's work surface.

30/60 Degree Cutoff Triangle Works in unison with the straight edge to cut a 30 or 60 degree angle.

45 Degree Cutoff Triangle

Works in unison with the straight

edge to cut a 45 degree angle.

Bevel Edge Maker

Bevel Edge Maker

This works in unison with the straight edge to make perfect 45 degree beveled edges.

Circle Maker

Circle Maker

This item works on any location of the work surface and helps to create perfect circles.

Lamp Wedge

Lamp Wedge

Use the lamp wedge to put a 30 degree bevel on the edge of a finished piece. This will allow the pieces to fit together more tightly, allowing for a smaller, stronger solder joint.

Super Slicer

The Super Slicer is a device that gives you the ability to make repetitive, perfectly parallel, ultra thin cuts in any material that will clear the throat height of the saw, which is 1 1/2" on the Taurus 3 and 1" on the Taurus II.2.

The Super Slicer can be adapted for use on other saws such as band saws, as long as the blade will pass through the ribs.

Examples where the Super Slicer can be useful are when cutting:

Pattern Bars, Streamers, Milfiori, and Virtually any other material that requires repetitive cutting.

The Super Slicer has the ability to cut slices as thin as 1/16".

RAM

Material is attached to this piece in order to be perfectly sliced.

BASE

Attaches to the work surface to provide a runway for the Ram. Also provided with the base are two removable pins that, when removed, the base can be used on any work surface without a grid.

Double-Sided Tape Strips

Used to attach material to the Ram.

Rubber Bands

Color coded for size and can also be used in addition to the Double Sided Tape Strips to attach material to the Ram for added stability.

Stabilizer Foot

The new Taurus 3 Ring Saw Blade Stabilizer reduces grommet wear dramatically. It also gives you more control and stability when cutting thicker material. The Stabilizer adjusts easily to accommodate different thickness material. Perfect when using any of the Taurus 3 blades.

This spectacular improvement will be included in all Taurus 3 Ring Saws starting in June 2005 at no additional cost.

The Stabilizer will fit all previously purchased Taurus 3 Ring Saws without any modifications and will be available at your favorite supplier at a nominal cost. Gemini Saw Company continues to add value to the Taurus 3 Ring Saw with yet another improvement to the best saw for cutting all types of material.

When to Use the Stabilizer Foot:

You can use the Stabilizer Foot any time you want better control.

However, it is recommended that you always use the Foot Stabilizer when using the Taurus 3 as a Handheld saw.

Taurus 3 Tips & Tricks

1. Try Using Coolant

You can use coolant with the Taurus 3 and it will help cutting and will not harm any of the materials in the saw. We find however that many persons can sit for hours cutting on saws as time passes quickly while doing so. Prolonged exposure to air born cutting fluid means be sure to choose a safe coolant.

**You do not have to use coolant with your saw, water works just fine.

A teaspoon of vinegar will help where hard water is prevalent. A couple of drops (two!) of dish washing liquid to your saw's water and running it is a great way to clean it, but be prepared for lots of suds and rinse it thoroughly!

In the past we have suggested using ice while cutting as this speeds up the cut! Everyone then thought that you had to use ice with it or not at all and we never meant for this understanding to occur.

What works better is the ice packs you get for coolers as it does not move around and make contact with the belt. Keep in mind that to the saw luke warm water is cold so for those of you in cold studios go ahead and use warm, (not hot), water. Your hands will love you.

2. BE SAFE: Use all blades with eye protection.

ALWAYS PROTECT YOUR EYES WHEN OPERATING A TILE SAW

If you lift up the eye shield for more clarity, then be sure to wear safety goggles or at lease glasses of some type.

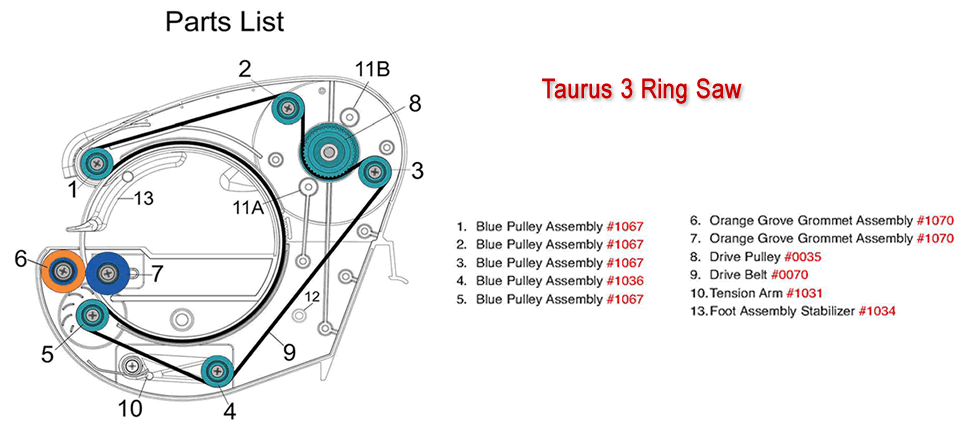

3. Taurus 3 Improvements on Part Numbers Starting with 81000

*We have made an improvement on Taurus 3's with part numbers starting with 81000 and above. We always try to make any improvements available to all previous saw owners and this is no exception. The change is in the blue pulleys #1 and #5 in your service manuals or as seen on our Tech Support page.

We found that by increasing the flange size of these wheels the drive belt is trapped and can't come off the pulley. What this does which we never knew before is that it traps the blade so that it cannot wander causing a new level of cutting stability and much longer grommet life. Add the stabilizer and you have made your saw a tour de force.

If you have an older Taurus and want the two new blue pulleys, order part# 1067.

Thank you for choosing Gemini Saw Company, Inc. and allowing us the pleasure of helping to

unleash your imaginations.

Sincerely,

Jesse Cogswell

President

Taurus 3 Video Support

© 2011-2019 Gemini Saw Company Europe